Every once in a while, something goes wrong. Many things, like a flat tire, are easy to diagnose. “Sounded like BANG Whomp, Whomp, Whomp. Looks like a flat tire, must be a flat tire. “

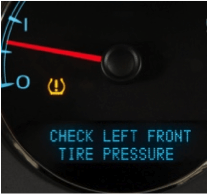

Other things are more complex. Let’s stick with tires for the moment. Newer vehicles come with pressure sensors in the tires. At some point, a low-pressure level triggers an alarm. A light on our console indicates the alarm. Fancier cars even tell you which wheel. The problem is, when you rotate the tires it now shows the wrong tire unless it was re-calibrated. Another problem is these sensors are battery powered inside each wheel (including the spare). When the battery fails, an alarm comes on even if the air pressure is good. Fortunately, although the indicator may be accurately indicating a flat tire, it will not prevent you from driving on it until the tire is un-repairable and the rim also has to be replaced. “No honey, I didn’t have a flat last night. But the car was driving funny and making a noise like “Whomp, Whomp, Whomp.”

Other things are more complex. Let’s stick with tires for the moment. Newer vehicles come with pressure sensors in the tires. At some point, a low-pressure level triggers an alarm. A light on our console indicates the alarm. Fancier cars even tell you which wheel. The problem is, when you rotate the tires it now shows the wrong tire unless it was re-calibrated. Another problem is these sensors are battery powered inside each wheel (including the spare). When the battery fails, an alarm comes on even if the air pressure is good. Fortunately, although the indicator may be accurately indicating a flat tire, it will not prevent you from driving on it until the tire is un-repairable and the rim also has to be replaced. “No honey, I didn’t have a flat last night. But the car was driving funny and making a noise like “Whomp, Whomp, Whomp.”

This all goes to show that diagnostics can be correct some of the time, incorrect some of the time and inconclusive some of the time. Yes, they are a valuable tool and extremely helpful, but should not always be blindly followed. The user needs to know the equipment and possess common sense at all times. Today we expect an internal diagnostic to trigger an alarm or text display, and then, not only explain what is wrong but also guide us through the repair or correction.

For example: “Open Door C, lift the Blue Lever marked C3, turn the Green Knob YY two turns to the left and remove the paper jam.”

What if the jam sensor is the broken part? Will the report get out by the end of business today?

I often see specifications defining the diagnostics and fault codes, which are written by someone whose job is writing.

They have never fixed or operated a machine in their life. The specification request may require a log of the previous 100 faults. I would hope there is a thought that just jumped out and said, “What do I care if the cause was for a fault 100 events back?” What is the last fault? Maybe the last five but be realistic when you ask for a feature. Another good one was a request for an indicator lamp to indicate loss of power! Yes, it can be done, but how about the obvious- if the lights are off, there is no power.

What happened to the folks who knew the equipment? There were craftsmen who could feel or hear if something was a little bit off and needed an adjustment before damage occurred. Those craftsmen are here with us in West Virginia.

We design fault codes to help the average user find a problem if one exists, but we also back up the automated diagnostic with real technicians and engineers in real time. Give us a call, we would love to talk and introduce you to equipment made as it should be made.