Last time, we discussed why the utilities supply 50 or 60 cycle (Hz) power and the aviation industry operates on 400 Hz power.

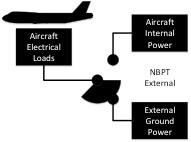

Obviously, the two systems are not compatible. 400 Hz is 6-2/3 times faster than 60 Hz and 8 times faster than 50 Hz. The speed of motors (and clocks) would be multiplied by the same factor. Also, a few things would just catch fire. However, we need a source of 400 Hz at the airfield so that aircraft can shut down their engines. The engines and internal generators burn fuel, create noise and produce undesired emissions.

The simplest approach would be to build a 400 Hz generator driven by an engine on the ground next to an airplane. But that would consume fuel, create noise and produce undesired emissions just like the aircraft. It would be a solution if no other power was available. However, usually utility power is not far away. The boarding bridge, hangar or other building will be using 50 or 60 Hz utility power.

But, didn’t we just say the two power systems were not compatible?

Yes, we cannot connect the two systems directly but there are ways of converting utility power to 400 Hz aviation power.

One way is to use a motor connected to the utility as the engine to drive a generator producing 400 Hz. This creates what is called a Motor Generator frequency converter, or “MG Set.” Electrical power to the motor generates horsepower out. The horsepower into the generator creates electrical power out. The engineering of the system ensures that the utility 50 or 60 Hz is correct for the motor and that the generator produces the proper voltage and 400 Hz frequency for the aircraft.

Although the MG Set solution is rather simple, it has a couple of drawbacks. First it is mechanical. The rotating parts require continuous lubrication. The air-cooling of the motor and generator create high ambient noise. Finally, because the efficiency of the MG Set is not good for normal and low loads, (50-70%) the operating power expense can be high.

A preferred method of frequency conversion is a Solid-State Frequency Converter (SSFC).

The solid-state design also takes power directly from the utility and converts it to a form acceptable to aircraft and military 400 Hz power systems.

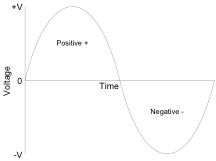

The front end of the SSFC rectifies the utility power and creates a direct current (DC) voltage. DC is a steady voltage that does not have a significant frequency component.

The DC is then switched by power transistors to create an alternating current (AC) waveform at the required frequency of 400 HZ. The efficiency of the SSFC is quite high at all loads; typically approaching 91-94%.

Although both types of frequency converter cost about the same, the solid-state frequency converter design and provide a significantly lower operating cost when compared to MG Sets. Fuel power engine generator sets may be the only choice if utility power is not available.